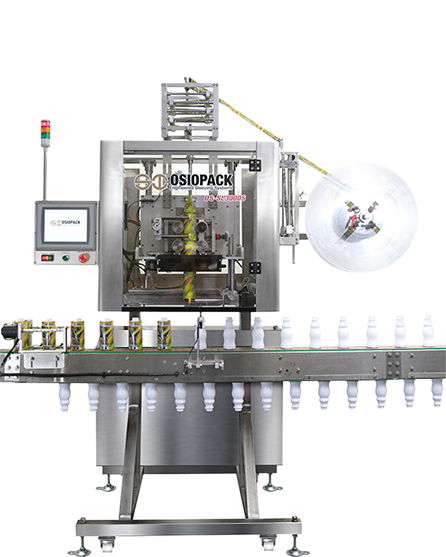

The SL3000S Sleeve System

The cantilevered design of the OS-SL3000S allows the freedom to move this machine onto any pre-existing conveyor line. The OS-SL3000S incorporates many of the standard features that our other line offers, such as Allen Bradley Drives and PLC, a new user friendly HMI interface, and stainless steel construction.

The extremely small footprint, simple operator interface and speeds up to 300 products per minute* makes this applicator one of the most cost effective machines in it’s class.

Advanced Features

Touch Screen: Provides seamless operation.

Stainless Steel Construction: Quality construction handles the most intense work environments.

Wide Product Capability: Size range from 30mm to 100mm diameters. Contact us for custom sizes.

Speed: Up to 300 bottles per minute*.

Stanley Knife Assembly: Results in high productivity and long blade life.

Convenience: Replacement parts availability.

Multi- Pack: Capable of applying to both round and square containers.

*For a 8oz container. Actual speeds are determined by product shape, conveyor speeds and film cut length.

Specifications

Dimensions

Height: 78.74″ (2,000 mm)

Length: 35.43″ (900 mm)

Width: 39.37″ (1,000 mm)

Weight

Approx. 1,763.7 lbs. (800 kg)

Electrical

220V, 3 Phase, 60Hz

Input Power

5kW

Material

PET / OPS / PVC

Label Thickness

40-50 Microns

Bottle Diameter

Ø30 x Ø100

Cut Length

40mm – 210mm

Key Features

Allen Bradley Drives and HMI Screen

PLC Control

Color Touch Screen

Quick and Easy Change Parts

Stainless Steel Construction

Servo Controlled Label Feeding Cutting Systems

Cantilevered design makes it easy to “roll” the machine onto any existing conveyor line.

Options

Six Stack Auto Roll Unwind Unit

Ethernet Connectivity

Film Perforation